How do you store your floss? Not the floss for the current project, but all the leftover floss and leftover bits of blended colors from previous projects, or projects you were going to stitch but didn’t.

How do you store your floss? Not the floss for the current project, but all the leftover floss and leftover bits of blended colors from previous projects, or projects you were going to stitch but didn’t.

For a long time, I kept all my floss in a couple of boxes. I think there was some in a plastic grocery bag too. But I got tired of digging through an increasingly large pile of floss for colors that were supposed to be there but somehow weren’t (have you ever thought you bought 5 skeins of 430 but were finally forced to conclude that you bought 5 skeins of 431 instead?).

So I tried some other things. Here they are in the order I tried them (which is also, not coincidentally, in increasing order of cost).

I had someone who was going to stitch a model for me find that she couldn’t do it and send all the materials back to me, so I had a lot of baggies with partial skeins. I decided to put ALL my floss in baggies, stick one end of a paper clip through a corner of the bag as a hanger, and then thread the paper clip onto a wire coat hanger. I filled up a couple of coat hangers and hung them in the closet. (The total cost was whatever a box of baggies costs plus a box of paper clips.) It looked fairly tidy and was out of the way, but still readily accessible. It was sort of a poor-man’s version of Floss-Away bags on binder rings. Unfortunately, it turned out that the paper clips tangled with each other so the baggies didn’t stay in order and it was hard to find the color I was looking for (and still hard to know for sure that it was or wasn’t there).

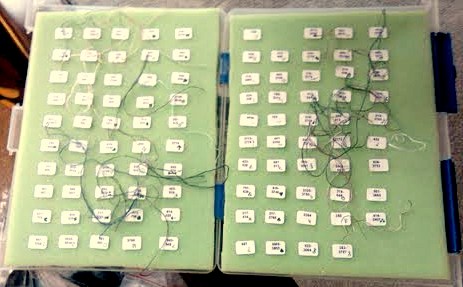

Then a friend moved away and gave me a bunch of those Sterilite chests of drawers (the size that will hold 3 reams of paper and can be stacked). You can get them at Big Lots. OK, I didn’t pay anything for these but I think they’re about $5 each. I needed some for Scarlet Quince supplies (cover stock, paper, labels, etc.) and devoted 2 of them to floss. I labeled each drawer with a range of floss numbers (200-499, 500-799, 800-999, 3000-3399, 3600-3799, and 3800-3899). I still had to dig through a pile of floss to find a color, but the piles were smaller. (Yes, this picture is of the drawers labeled for SQ supplies, not for floss.)

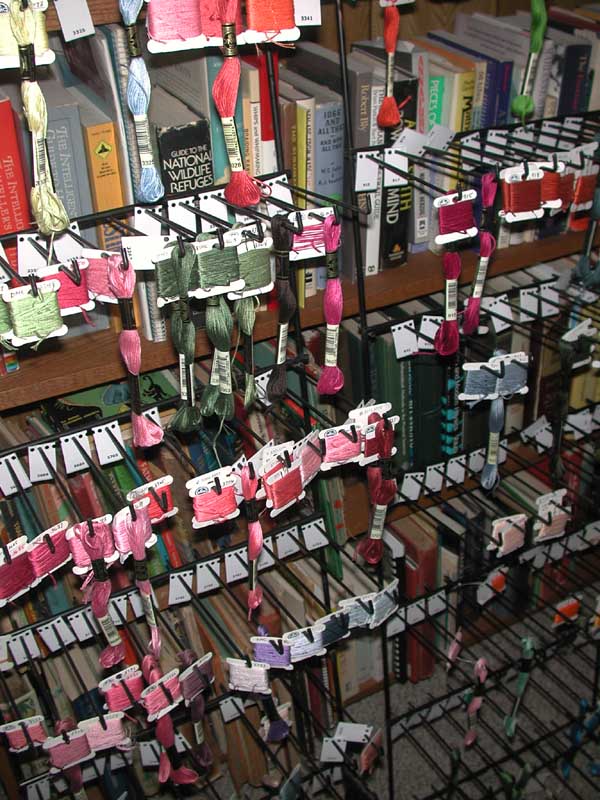

That continued until our local needlework shop, Ginger’s, went out of business. She sold all her inventory and all the store fittings, including the racks where she hung all the DMC floss. I got dibs on the floss racks, measured them, and went home and measured the space I had in mind for them (below a counter in the family room that connects to the kitchen, originally set up as a bar). I hypnotized myself into believing they would fit there perfectly and called Ginger and told her they would fit my space and I’d be back for them. I brought them home and they were not at all close to fitting. For a long time I didn’t put them up anywhere because you don’t want a forest of 6″ hooks anywhere where someone might stumble into them in the dark.

Finally I did put them up against the counter after all but they stuck up above the counter some. One didn’t fit behind the counter so I put it on another wall. They were made to go on pegboard but I just hung them on nails. I knew the floss would get dusty out in the open and I planned to make a cover for it but that didn’t work out. Our couch is a couple of feet away from the wall so there’s an alleyway behind the couch where I can get at the floss but it’s not a high traffic area. Nevertheless, somehow people kept crashing into the racks (especially the one on the end) and knocking floss off or knocking the whole thing down. Finally I got enough of that. I didn’t get a picture of them while they were on the wall because MRA was so gung-ho to get going on my NEXT system, but you can see there’s a lot more storage capacity than any individual contributer really needs.

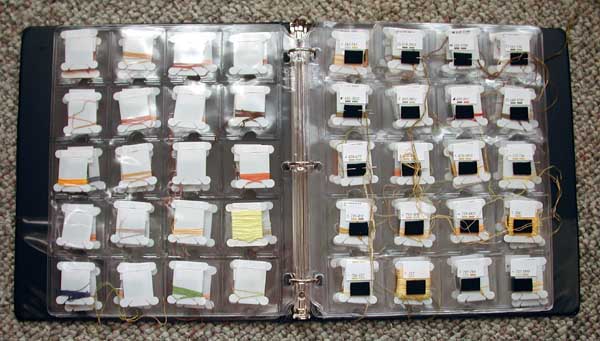

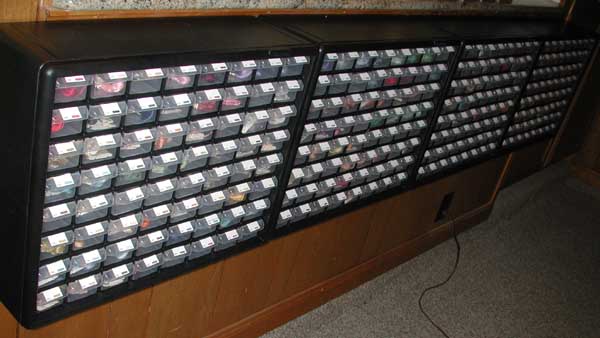

SO I bought a set of little drawers, one for each DMC color. There are 8 cabinets, each with 64 drawers. They’re made by Akro-Mils, part number 10164, and I got them on Amazon for $28.59 each and free shipping. Each cabinet is 20″ x 16″ x 6.5″. The drawers are 5.25″ long by 2″ wide and 1.5″ deep. They’re slightly too short for a skein of floss (it has to be curved a little to fit) and bobbins fit just fine. You can get maybe a dozen skeins in a drawer. There are 512 drawers and only 469 “normal” DMC colors (I’m excluding the variegated ones and rayon etc.) so I have some extra drawers for pearl cotton, needles, silks, beads, extra bobbins, etc.

I also made a set of floss labels for the drawers with the number and a big color swatch. (People have been asking for something like this for a while, and we will make them available as soon as I work out the RGB values for the 16 newest DMC colors.) The labels fit pretty well on the drawer pulls and the color swatches are really helpful because you don’t have to look at every number — you can jump to the next drawer with approximately the right color on the drawer pull.

I think this will be my last system. The cabinets are reasonably compact (they don’t stick out as far as the hooks), they are not going to fall off the wall, and the floss is protected from dust. If you wanted to be a little more frugal with your money or your space, you could have 2 or 3 colors per drawer.

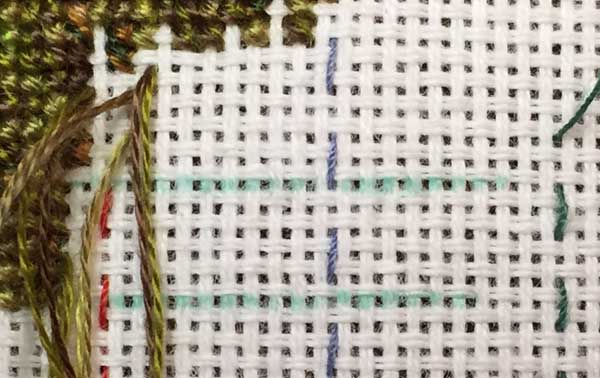

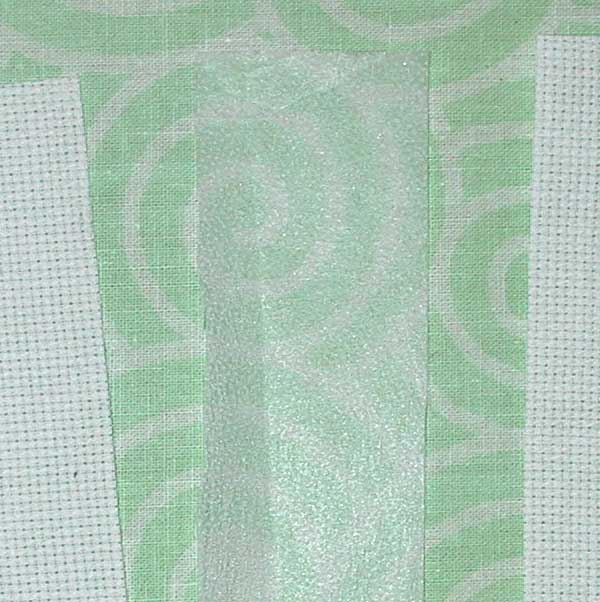

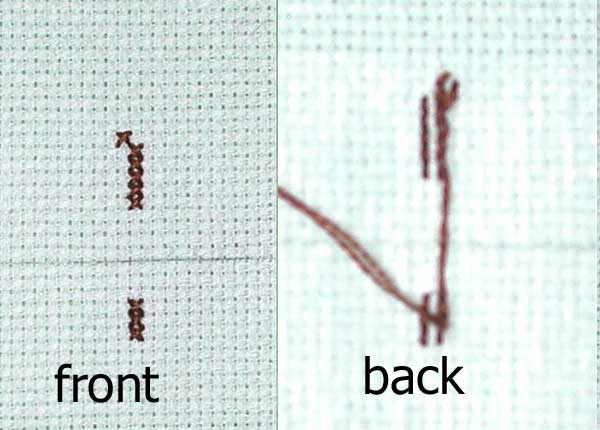

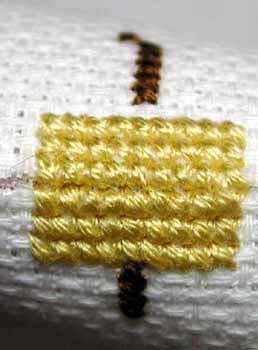

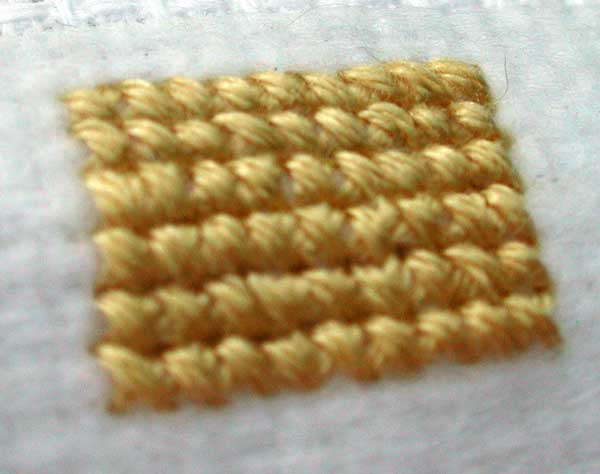

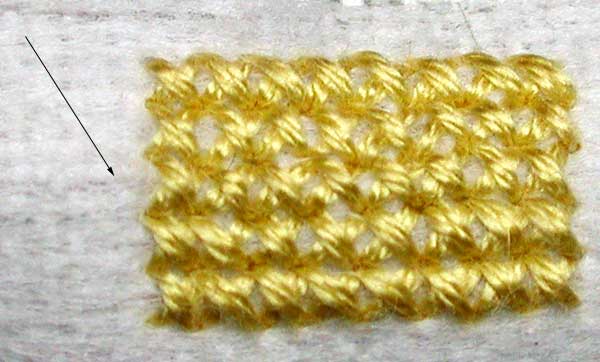

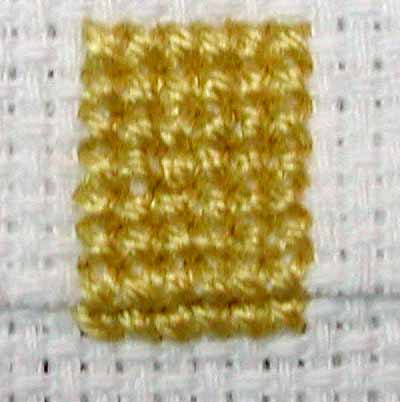

Here’s a little swatch stitched across the join. Can you see it? It’s between the 3rd and 4th row of yellow stitches. You can see it if you know where it is, but I think it would be OK. The problem is, since it is only reinforced on one side, it breaks to the front (right photo), so you would not want to use it for a pillow or anything that didn’t have firm support behind it.

Here’s a little swatch stitched across the join. Can you see it? It’s between the 3rd and 4th row of yellow stitches. You can see it if you know where it is, but I think it would be OK. The problem is, since it is only reinforced on one side, it breaks to the front (right photo), so you would not want to use it for a pillow or anything that didn’t have firm support behind it.

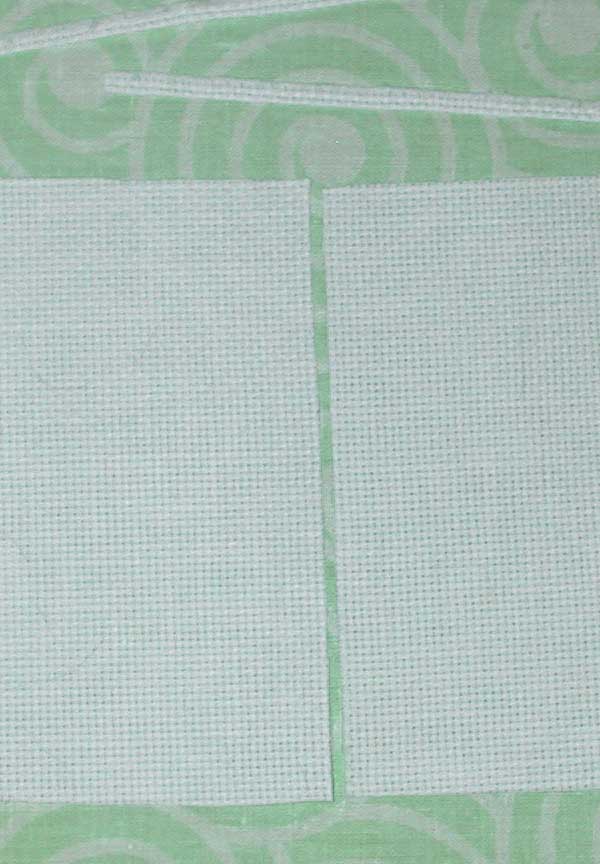

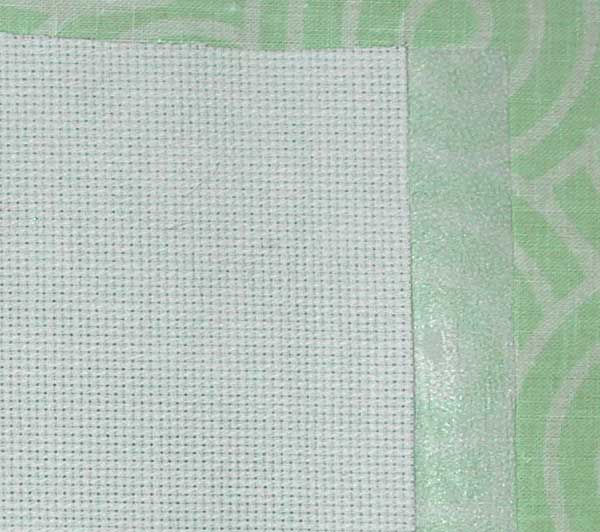

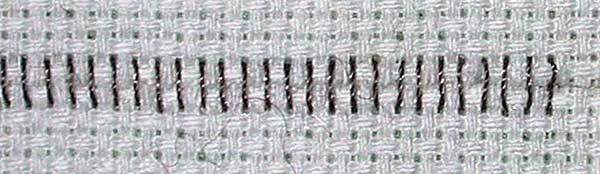

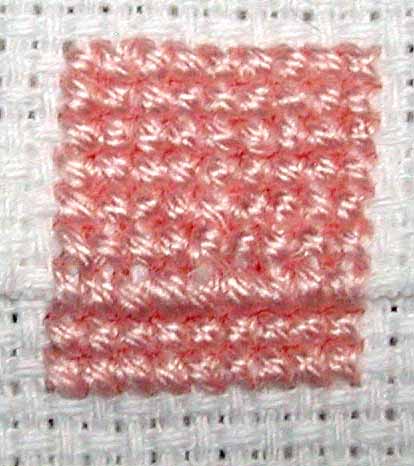

I first tried overlapping the two pieces and starting above the overlap and stitching straight down. I didn’t pin the pieces and had a lot of trouble with the fabric shifting and pivoting. As you can see, the last row of stitches (where the overlap ends at the bottom) is wider than the rest but even worse, the next row is too narrow.

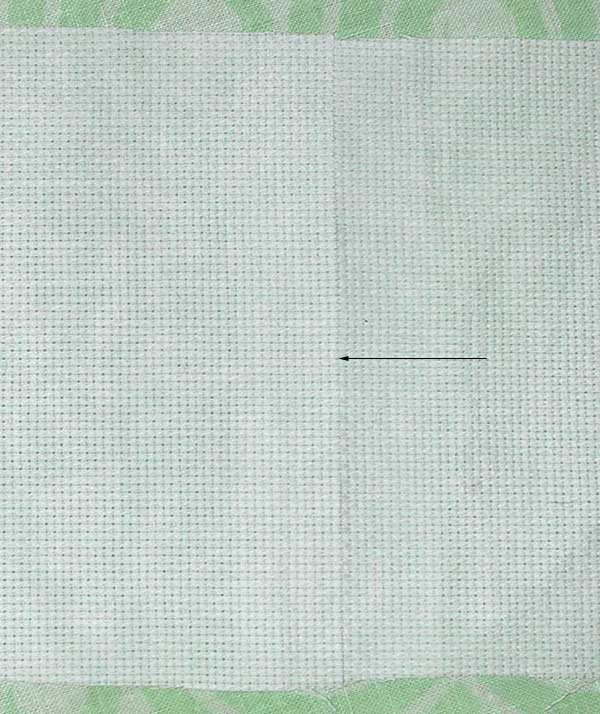

I first tried overlapping the two pieces and starting above the overlap and stitching straight down. I didn’t pin the pieces and had a lot of trouble with the fabric shifting and pivoting. As you can see, the last row of stitches (where the overlap ends at the bottom) is wider than the rest but even worse, the next row is too narrow. Next, I tried stitching the bottom row of the overlap first, and continued with the two rows below that. Then I went back up above the overlap and stitched down to the row I had stitched first. This time, I pinned it, which helped a lot. Also, by stitching the last row of the overlap first, it was easier to get the holes lined up for that row. It still is noticeable though. It seemed to me that now the problem was cumulative error in lining up holes pushing toward the “bump” row.

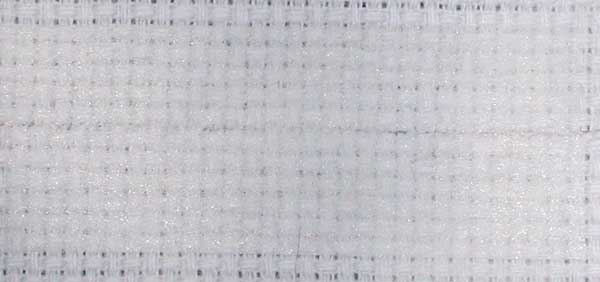

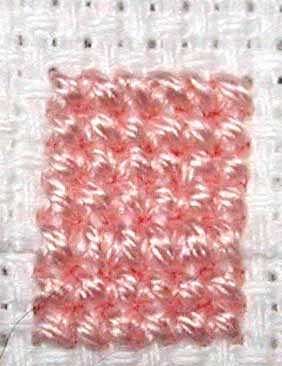

Next, I tried stitching the bottom row of the overlap first, and continued with the two rows below that. Then I went back up above the overlap and stitched down to the row I had stitched first. This time, I pinned it, which helped a lot. Also, by stitching the last row of the overlap first, it was easier to get the holes lined up for that row. It still is noticeable though. It seemed to me that now the problem was cumulative error in lining up holes pushing toward the “bump” row. Finally, I tried starting with the bottom row of the overlap, then stitching the two rows below it, then turning the fabric upside down and stitching away from the “bump” row. This worked better and it was a little easier to line up the holes. They never really do line up, though. You have to find the hole on the bottom piece of fabric and then feel around in the top piece until you find the hole. And although this is a small sample and it’s hard to tell from the picture, the bottom row of the overlap IS noticeably wider than the surrounding rows. It is no worse than the effect you get sometimes stitching on linen when the weave is uneven, but you can see it, and in a row two feet long, it might be quite noticeable.

Finally, I tried starting with the bottom row of the overlap, then stitching the two rows below it, then turning the fabric upside down and stitching away from the “bump” row. This worked better and it was a little easier to line up the holes. They never really do line up, though. You have to find the hole on the bottom piece of fabric and then feel around in the top piece until you find the hole. And although this is a small sample and it’s hard to tell from the picture, the bottom row of the overlap IS noticeably wider than the surrounding rows. It is no worse than the effect you get sometimes stitching on linen when the weave is uneven, but you can see it, and in a row two feet long, it might be quite noticeable.